A common metric for 'soft' materials is ASTM D2240 Shore Durometer which is a family of tests that gauge the penetration distance of a so-called indentor when a force is applied. The indentors have various specifications for different materials/tests and range from a relatively large diameter (flat-ish) to quite small (sharp-ish).

from http://pitstopusa.com/n-2850-how-to-maximize-street-tire-grip-on-dirt.html via google images

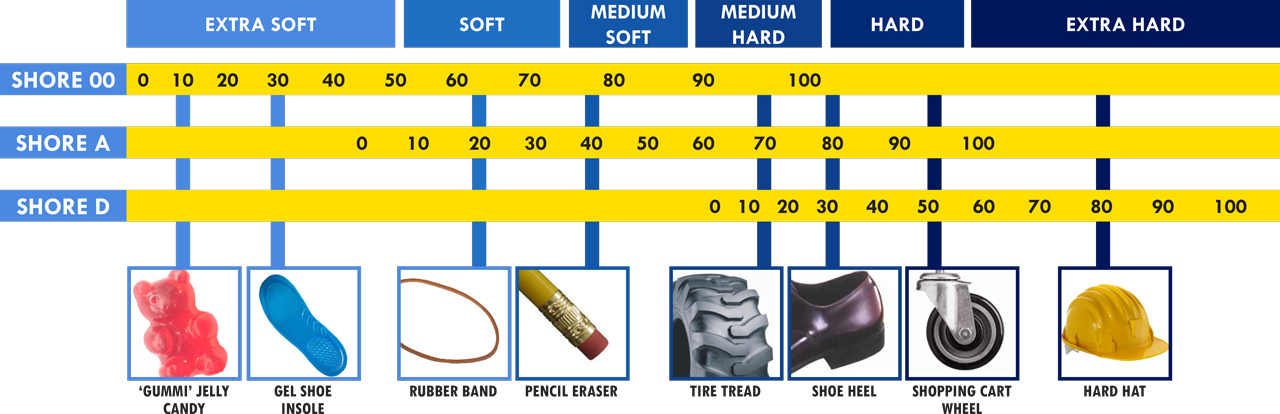

Common values for some common tests/materials are shown below

from http://www.smooth-on.com/Documents-Duromete/c1351_1370/index.html via google images

For materials that are not so soft (like metals) a similar method to shore durometer is the Rockwell scale where the plastic (permanent) deformation is measured when pressing an indentor into the test material.

By Djhé (Own work) [GFDL (http://www.gnu.org/copyleft/fdl.html) or CC BY-SA 3.0 (http://creativecommons.org/licenses/by-sa/3.0)], via Wikimedia Commons

An alternative for hard objects is the Vickers hardness test which is based on the surface area of indentation of a standard diamond pyramid indentor.

All the above metrics are experimentally determined but provide standard comparative controls for materials.

ASSOCIATED LINKS

No comments:

Post a Comment